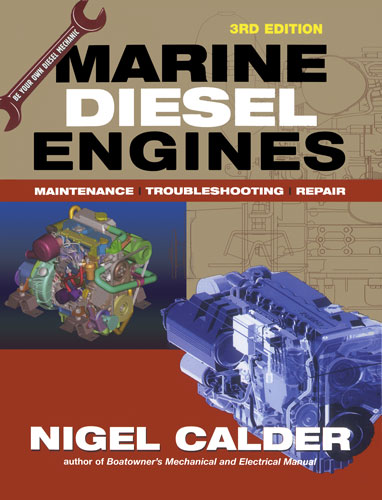

Marine Diesel Engines/Судовые дизельные двигатели

Издание на английском языке

For very good reasons, the diesel engine is now the overwhelming choice for sailboat auxiliaries, and it is becoming more popular in sportfishing boats, high-performance cruisers, and large sportboats. Diesels have an unrivaled record of reliability in the marine environment; they have better fuel economy than gasoline engines; they are more efficient at light and full loads; they emit fewer harmful exhaust pollutants; they last longer; and they are inherently safer because diesel fuel is less volatile than gasoline.

См. также Дизельный двигатель + DVD на русском.

Content

List of troubleshooting charts

Preface to the third edition

Preface to the second edition

Introduction

One

Principles of Operation

Compression Ignition

Converting Heat to Power

Expansion and Cooling

Gasoline Engines

Cost and Power-to-Weigh

Types of Diesels

Principal Engine Components

Two

Details of Operation

Section One: The Air Supply

Volumetric Efficiency

Naturally Aspirated Engines

Superchargers and Turbochargers

Intercoolers and Aftercoolers

Section Two: Combustion

The Importance of Turbulence

Injector Spray Patterns

Techniques for Creating Turbulence

Section Three: Fuel Injection

Jerk (In-Line) Pumps

Distributor (Rotary) Pumps

Unit Injectors

Common Rail Systems

Injectors

Lift Pumps

Section Four: Governors

Simple Governors

Vacuum Governors

Section Five: Electronic Engine Controls

Networking

Limping Home

Section Six: Keeping Things Cool

Raw-Water Cooling

Heat Exchanger Cooling

Keel Cooling

Wet and Dry Exhausts

Three

Routine Maintenance: Cleanliness is Next to Godliness

Section One: Clean Air

Routine Maintenance

Section Two: Clean Fuel

Lubrication

Contamination

Fuel Handling

Fuel Filters

Section Three: Clean Oil

The API "Donut"

Oil Changes

Changing Filters

Section Four: General Cleanliness

Clean Water

Clean Electrical Systems

A Clean Engine

Scheduled Overhauls

Section Five: Winterizing

Four

Troubleshooting, Part One: Failure to Start

Section One: Failure to Crank

Water in the Engine

Starter Motor Does Not Crank

Inertia and Preengaged Starters

Circuit Testing

Motor and Solenoid Disassembly, Inspection, and Repair

Section Two: Failure to Fire

An Unobstructed Airflow

Achieving Ignition Temperatures

Fuel Problems

Five

Troubleshooting, Part Two: Overheating, Smoke, Loss of Performance, and Other Problems

Overheating

Smoke

Loss of Performance

Oil-Related Problems

Inadequate Turbocharger Performance

Problems with Engine Instrumentation

Six

Repair Procedures, Part One: Cooling, Exhaust, and Injection Systems

The Cooling System

Water Pumps

The Exhaust System

Governors

Fuel Injection Pumps

Injectors

Gaskets

Seven

Repair Procedures, Part Two: Decarbonizing

Preparatory Steps

Cylinder Head Removal

Valves

Cylinders

Pistons and Connecting Rods

Piston Rings

Replacing Pistons and Connecting Rods

Replacing Cylinder Heads

Retiming an Engine

Accessory Equipment

Eight

Marine Transmissions

Planetary Transmissions

Two-Shaft Transmissions

Variations on a Theme

Shaft Brakes

Transmission Maintenance

Troubleshooting and Repairs

Nine

Engine Selection and Installation

Section One: Engine Selection

Matching an Engine to Its Load

How Much Horsepower Do You Need?

ВНР, SHP, and Auxiliary Equipment

Section Two: Propeller Sizing and Selection

Propeller Sizing

Propeller Selection

Section Three: Connecting the Transmission to the Propeller

Couplings

Engine Alignment

Constant-Velocity Joints

Shaft Seals

Struts and Bearings

Section Four: Auxiliary Systems

Ventilation

Fuel Tanks

Cooling

Exhaust

Auxiliary Equipment

Some Electrical Considerations

Serviceability

Postscript: Diesel-Electric Propulsion

Appendices

Glossary

Index

Диагностирование электронных дизелей

Диагностирование электронных дизелей  The Marine Electrical & Electronics Bible. A practical handbook for cruising sailors. Third edition

The Marine Electrical & Electronics Bible. A practical handbook for cruising sailors. Third edition  Boatowner’s Mechanical and Electrical Manual. Fourth Edition/Руководство судовладельца по механическим и электрическим системам

Boatowner’s Mechanical and Electrical Manual. Fourth Edition/Руководство судовладельца по механическим и электрическим системам